영신컨설턴트 (02)529 8803 ystcha@naver.com 2022 7

천공 후 로드를 인발하면서 지반과 시멘트를 지중에서 교반하여 기둥형성하고 기둥의 직경 강도 투수성 중요합니다.

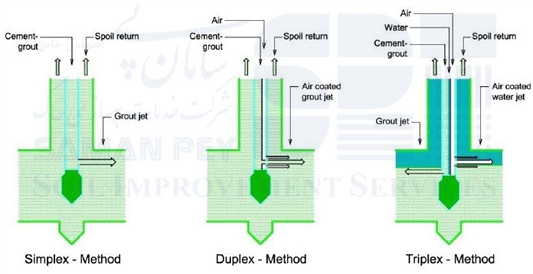

그라우팅관(공기, 물)에 따른 3 가지 종류

단일관 그라우팅관, 이중관 그라우팅관 공기관, 3중관 그라우팅관 공기관 물관

|

||

|

|

|

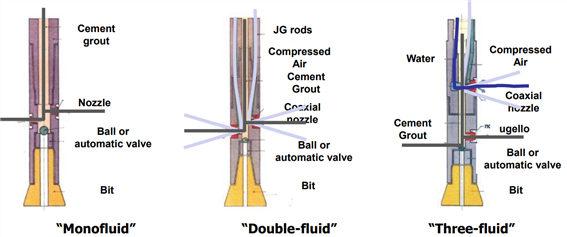

jet grouting 분사

jet grouting 압력

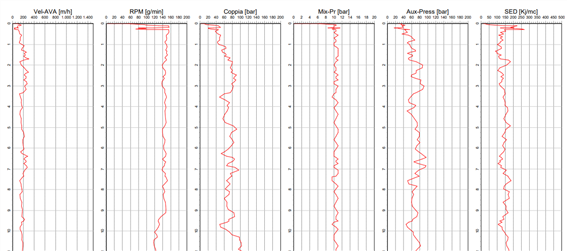

측정요소

controlling parameters that can determine the quality of execution of the elements jetting are mainly (Tornaghi, 1993; Croce et al., 2004):

(i) 로드 회전수 the speed of rotation of the rods injection (rev/min)

(ii) 인발속도 the lifting rate the rods (m/h)

(iii) 물 시멘트 비 the cement water ratio

(iv) 물 시멘트 유량 the suspension flow (m3/h)

(v) 물 시멘트 주입압력 injection pressure (in MPa) and

(vi) 노즐의 면적과 수 the area and number of the injection nozzles.

흙 시멘트기둥의 직경 강도 투수성

The criteria used for checking the effectiveness of jetting are mainly the diameter of the columns, the resistance, and the permeability of the elements, as well as the costs of construction.

흙 시멘트기둥의 강도 투수성은 로드 회전수와 인발속도에 따라 변한다.

The latter depends mainly on the speed of execution (i.e. the speed of rotation and rods withdrawal), the cost of the injected material, and the costs of the personnel and equipment required on site.

it is possible to state that:

(i) With the increasing strength of the soil the energy needed to disintegration of the material increases. The energy is determined by the speed of the jet from the area of the nozzles and the injection pressure;

흙 시멘트기둥의 강도는 제트 속도

(ii) At constant soil strength resistance, the size of the jet grouted elements increases with the increasing energy. This is determined by the speed of rotation and extraction of the rods;

(iii) To obtain a constant dimension of the elements with the increasing depth, it is necessary to increase the energy and the execution time, since the soil strength grows with the depth;

심도별 일정 직경의 기둥을 위해 심도별 에너지의 증가 필요

(iv) The final strength of the jet grouted elements depends on the composition of the cement, the water/cement ratio, and the soil characteristics. The water/cement ratios are not a constant but they range between 0-6 and 1-5. However, the latter is a value that should not be exceeded. In order to obtain rapid curing time, portland cement is used. On the other hand if a good treatment in a chemically aggressive environment is required, the pozzolan cement is desired.

energy balance

The applied energy per unit length of column is calculated at the pump by the following formula for single fluid treatment (e.g. Tornaghi, 1993)

단위 길이당 에너지 applied energy per unit length of column

ES= Q x P / Vs

Q 유량 the grout flow rate (m3/h),

P 유압 grout pressure(MPa) and

Vs 인발속도 monitor lifting rate i.e. treatment speed(m/h) gives an unit of MJ/m.

The product P x Q is simply the power (kW), while the specific energy is referred to the column length (Tornaghi,1993). When the mean diameter D (m) is known by visual inspection or adequate coring and translated in terms of specific volume of column VC (m3/m), the volumetric specific energy, as a function of applied energy is obtained (Tornaghi and Pettinaroli, 2004)

ES= Q x P / VC x Vs

The specific energy ES (MJ /m3) necessary for the treatment of the unit volume of soil is a single design parameter taking into account both grading and relative density or consistency characteristics of native soil. VC (the mean specific column volume)

'기타' 카테고리의 다른 글

| 암반 현장 투수시험기(LUGEON TEST ) (0) | 2022.08.29 |

|---|---|

| 연약지반 심층혼합처리 DCM (deep cement mixing) 시공관리 (0) | 2022.08.26 |

| 지중압력 측정 (0) | 2022.08.01 |

| 제트그라우팅 (Jet grouting) 측정 (0) | 2022.07.29 |

| 디지털 사진 (digital image corellation, DIC) 지반 변형 측정 (0) | 2022.07.29 |